Product Resources

PDF Downloads: Product info, SDS, and white papers

🗎 Ana-Zyme G Product Sheet

🗎 Ana-Zyme G SDS

🗎 Impact of Ana-Zyme G on the Anaerobic Digestion of Wastewater Fatty Acids

🗎 Impact of Ana-Zyme G on Biogas Production in High F.O.G. Anaerobic Systemss

Ana-Zyme G

Speeding anaerobic degradation of grease

- Quickly converts grease (long chain fatty acids) into methane gas

- Allows anaerobic systems to accept higher levels of grease into their processes

- Works between 15°C and 60°C and pH 6.0 and 8.5

Anaerobic digester upset & troubleshooting:

Get answers and solution recommendations in 2 days when you complete this form.

$205.00 – $8,460.00

Product Info

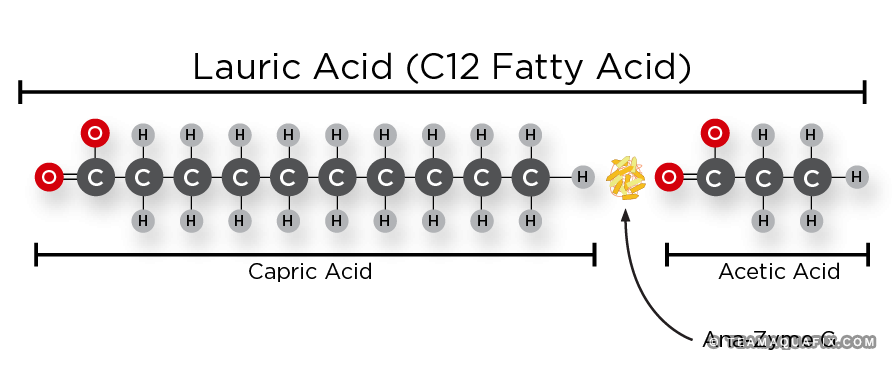

Ana-Zyme G is formulated to provide immediate reduction of fat, oil, and grease in anaerobic digesters and lagoons to avoid issues with grease caps and foaming. The biocatalysts in Ana-Zyme G rapidly speed the breakdown of complex fat molecules into simple short-chain fatty acids which then break down to acetic acid, a compound used in methanogenesis.

The goal of this product is to limit volatile acid accumulation, while also increasing biogas generation, and improving volatile solids destruction.

Ana-Zyme G can degrade a range of fatty acids such as linolenic, oleic, stearic, and palmitic as well as fish oils, triglycerides, dairy, and egg fat. The production of short-chain fatty acids is very important as part of the acidogenesis–methanogenesis process.

High Levels of Grease in Anaerobic Digesters

FOG must undergo several steps to be converted into the ideal food substrate for methanogens, acetate: disintegration, hydrolysis, and β-oxidation.

Limitations in the rates of any of these steps can lead to uneven degradation of FOG, which results in variable volatile acid loading on methanogens. Variable loading of volatile acids can easily overwhelm methanogens leading to accumulation of volatile acids, eventually resulting in a drop in digester pH. These impacts are exacerbated in systems with high FOG loading.

However, FOG can be made into an excellent food substrate for anaerobic digestion, due to their high COD content, as well as their high potential to generate large quantities of acetate or acetic acid. It just needs a little processing to get there.

Ana-Zyme G and Anaerobic Grease

Ana-Zyme G acts as a catalyst to naturally occurring bacteria to aid in the breakdown of FOG, which prevents the overloading of methanogens and frees up this new food source. Ana-Zyme G does this by targeting triglycerides and long-chain fatty acids to convert them evenly into short-chain fatty acids. This stabilization of fatty acid degradation allows methanogens to better acclimate to fatty acid loading. They are then able quickly uptake these fatty acids, reducing the chances of volatile fatty acid accumulation. In addition, Ana-Zyme G prevents the accumulation of undegraded fats in a system, which enhances volatile solids destruction, particularly in systems with limited mixing such as lagoons.

Dose Rate

Product Pairings

Applications and Benefits

- Anaerobic digesters/lagoons for:

- Dairy processing

- Meat processing

- High fat food processing

- Eliminates grease caps

- Avoid foaming due to fats, oils, and greases

- Boosts health of bacterial population

- Prevents buildup of fatty acids

- Improves VA:ALK ratio

Technical Expert 1 –

Great Product