Building Better Anaerobic Digester Studies

How our in-house pilot studies replicate field conditions to generate meaningful methane data.

by Dan McKeaton, Senior Researcher and Anaerobic Specialist

In a previous blog we discussed some of the pros and cons of BMP studies on anaerobic digesters. While they’re excellent for showing how much methane can be produced from a food substrate, they have less utility as a representative site study and will only work well in some cases. The best-case alternative is an on-site pilot-scale digesters using actual feedstock and seed sludge—but these are often cost-prohibitive and labor-intensive. Because of this, we’ve developed lab scale pilot studies to understand the impacts of different treatment applications in anaerobic digesters and produce realistic results.

To make these pilot studies truly representative, we have a number of hurdles we need to address, including these 4 main points.

-

-

- Seed sludge must be representative of the site.

- Feedstock should be collected fresh at a minimum of monthly to ensure the sample does not degrade or deteriorate during storage.

- Operating conditions require precise control to ensure our digesters are operated the same as the field digester in question.

- Measurements need to be dependable and address site concerns.

-

Seed Sludge and Feedstock Must Be Site-Representative

Collection of representative feedstock and seed sludge are a major challenge for many digester sites. A well-positioned sampling port for seed sludge tends to aid greatly in anaerobic sampling consistency. However, if you have a digester with decent mixing, sampling tends to be fairly reliable for seed sludge in most cases. Feedstock sampling can be a similar challenge, especially for sites that have variable digester feeds throughout the week. A composite of properly proportioned feedstock is necessary in these cases to have an effective study. However, many sites that accept consistent loading rates can get away with a grab sample from standard operation days.

During our lab-scale digester testing, we prescreen samples for volatile solids (VS), total solids (TS), soluble COD, and pH to ensure these are consistent with the expected values for the site to in order to begin studies. If you’re interested in participating in either our Anaerobic Operational Change Study or Anaerobic Optimization Study, but unsure about sample collection, we’re happy to help with guidance and logistics.

Controlled Operating Conditions Are Critical

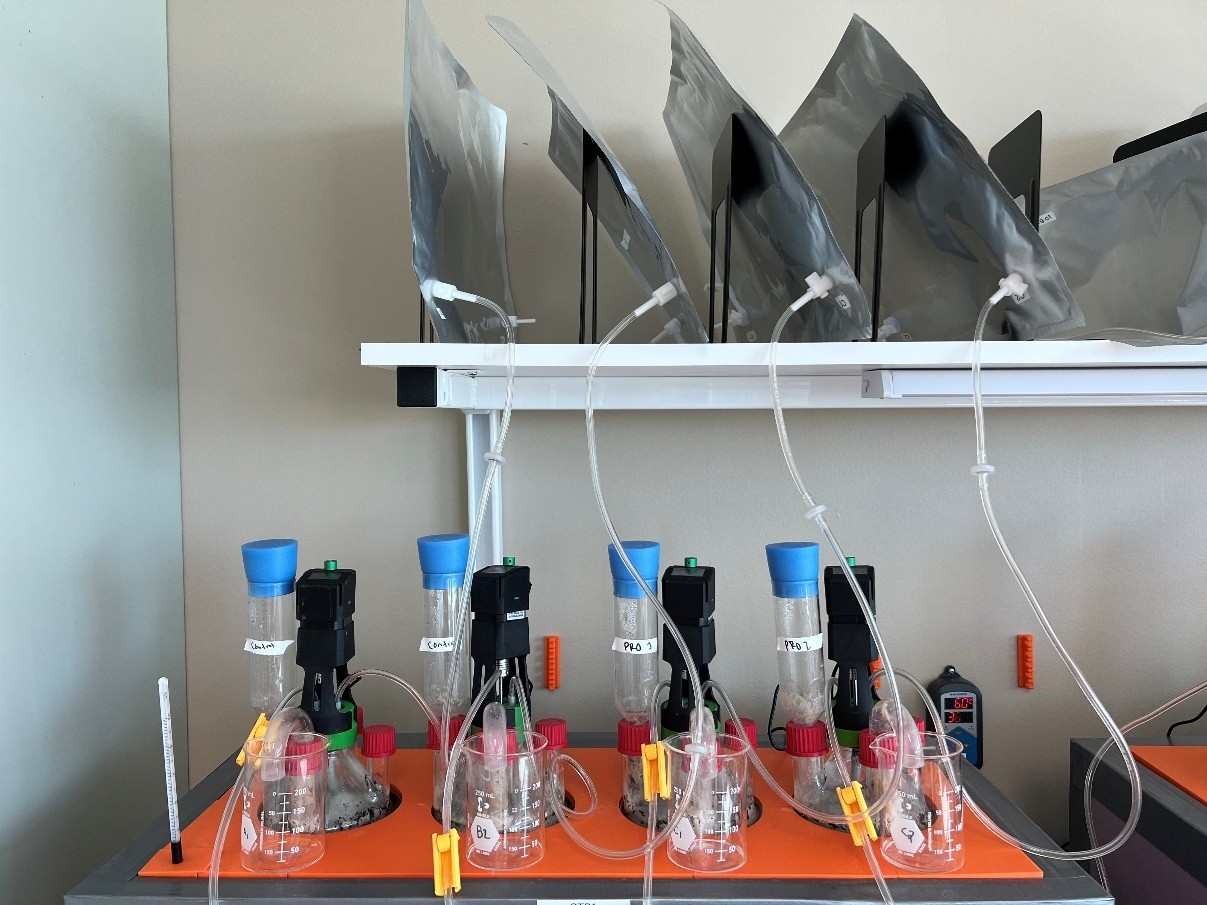

Replicating field conditions requires precise control of temperature, pH, and SRT(solids retention time)/HRT(hydraulic retention time), along with reliable mixing.

Temperature

We developed a constant temperature bath, utilizing a 20-gallon long style aquarium to contain water, the heating elements, and thermometers, to house 4 of our 2-liter anaerobic mixed digesters. We verify the temperature daily with a certified thermometer and calibrate the thermostats as needed. In the case of thermostat or heater failure in the main system, we also include a backup aquarium heater to help keep the test inside mesophilic range. Additionally the constant temperature bath is insulated with styrofoam to minimize strain on the heating elements and prevent shifts in temperature throughout the day. To position our digester bottles we have a 3D printed lid to prevent evaporation as well as bases to provide additional space between the heating element and the digester bases.

pH Control

We’re currently looking into automated pH control for the digesters in necessary cases. At this point, we use a calibrated pH probe and check the digester effluent pH following each feed. In standard operation, we don’t see any issues with maintaining pH. Studies with very high loading rates may benefit more from automated pH maintenance to prevent potential pH crashes. In general, if we observe a pH control issue in these studies, this suggests a potential pH maintenance issue on site which may be helpful to address in the study anyway.

Loading Control

We calculate the loading rate in the digesters to match the site HRTs and feed the digesters 3 days per week unless adjustments are needed. While shorter HRTs require larger feedstock sampling volumes to maintain digesters, we have not had any challenges adjusting to HRTs in sites we’ve had to mimic. If temperature, loading rates and pH are copied effectively, digesters should operate very similarly to the sample site digesters which ensures representative data.

Meaningful, Site-Relevant Measurements

Once quality control is considered, the next factor is to collect appropriate measurements. In our case, we typically collect gas in 10 L gas bags and use a handheld gas meter to take gas quality measurements and calculate gas volume based on pump speed. Gas quality measurements are reported as percentages for methane, carbon dioxide, oxygen and nitrogen. Hydrogen sulfide is report as ppm. We have been exploring using continuous gas production monitoring for things like enzyme testing to show when the enzymes added have the most relevant impact, but this typically goes outside the scope of a normal pilot study. We currently are also measuring TS/VS data in the digester effluent as well as soluble COD to get a good sense how anaerobic digestion is impacting solids reduction and COD reduction. We can add more testing parameters on to studies as needed so if you have any questions about taking other measurements, please let us know. Example data for methane percentages and methane generation are listed below. Let us know if you have any questions about these studies! We’re continuing to optimize these throughout the year to provide additional testing as well as routine metals analysis, analysis for nitrogen, short chain fatty acids, and polysaccharides, as well as ATP for biomass activity.

Anaerobic Testing Solutions

Anaerobic Operational Change Study

The Anaerobic Operational Change Study is designed to accurately predict the impact of a specific operational change to an anaerobic digester. This 10 week study includes a comprehensive prescreening for metals, TS, VS, pH, soluble COD, Anthrone, Lowry, and SCFA’s (short chain fatty acids). Each testing package will include site specific observations on digester performance.

Anaerobic Optimization Study

The Anaerobic Optimization Study is designed to expand on the Anaerobic Operational Change Study to determine how effective several different treatment modifications are on digester operation. This could include supplementation of combinations of different nutrients, enzymes, or operational changes to determine what changes are most likely to lead to improved anaerobic digester performance. This 10 week study includes a comprehensive prescreening for trace metals, TS, VS, pH, soluble COD, Anthrone, Lowry, and SCFA’s (short chain fatty acids).

Biochemical Methane Potential Study

The BMP (Biochemical Methane Potential) Study is a basic laboratory procedure used to show potential methane yield in an anaerobic digester from a given substrate. This 4 week study includes a simple prescreening for TS, VS, and soluble COD.

About the Author

Dan McKeaton is a senior researcher and anaerobic digestion specialist at Aquafix Inc. He has performed wastewater research for over 10 years and has presented his work at WEFTEC’s technical symposium on the impacts of quaternary ammonium cation disinfectants on biological wastewater treatment. Currently, Dan is responsible for designing and executing our studies on anaerobic digestion and developing anaerobic products with a current focus on controlling hydrogen sulfide production in anaerobic digesters.