Product Resources

PDF Downloads: Product info, SDS, and white papers

🗎 Qwik-Zyme L Product Sheet

🗎 Qwik-Zyme L SDS

🗎 Fatty Acid and Grease Removal in

Wastewater by UW-Stevens Point

Qwik-Zyme L

Immediate breakdown of fat, oil, and grease

- Mitigate foaming and FOG filament outbreaks

- Removes oil scum in clarifiers and aeration basins

- Improves BOD removal and effluent TSS caused by high incoming FOG

- Use anywhere grease builds up, excellent in systems with high loading

$210.00 – $8,460.00

Product Info

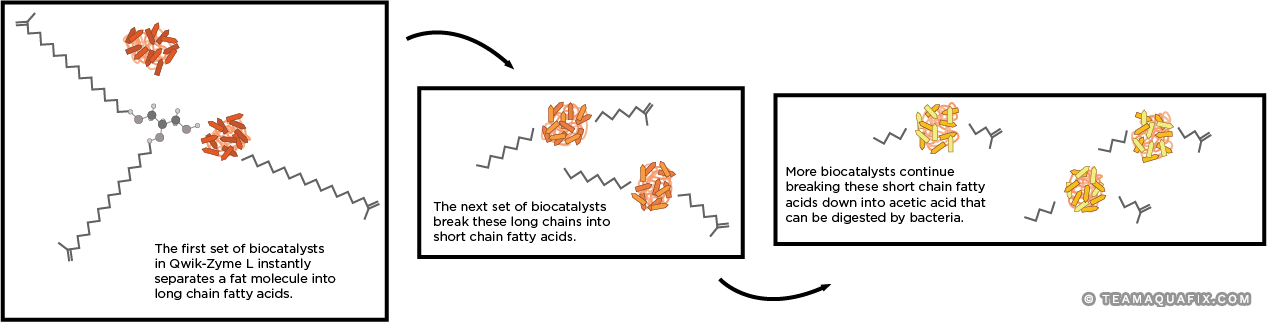

How Qwik-Zyme L Works:

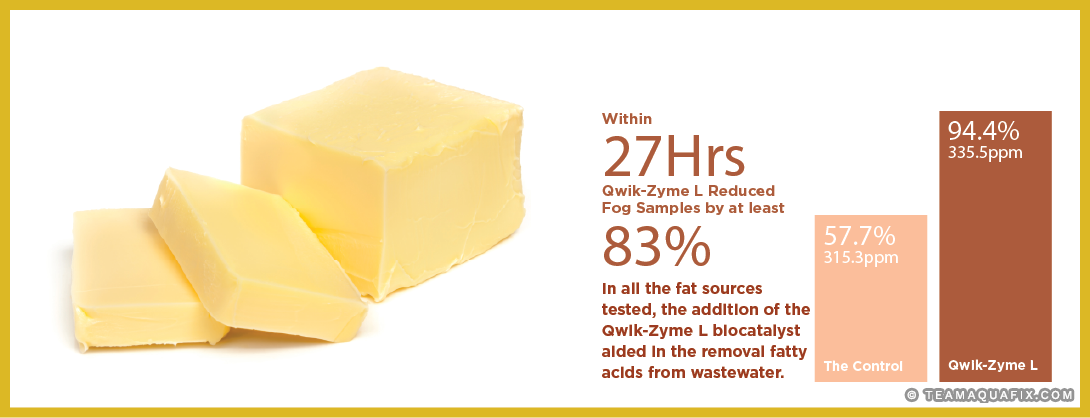

Qwik-Zyme L is an excellent grease degrader in sequencing batch reactors (SBR), wastewater treatment plants, equalization tanks, and food and egg processing plants. It can degrade a range of fatty acids such as oleic, steric, and palmitic as well as fish oils, triglycerides, milk, and animal fats. Qwik-Zyme L works best from pH 6-9 and from 45–140°F (8 to 60°C) and is formulated for aerobic treatment systems. For similar issues in anaerobic process, see Ana-Zyme G.

Qwik-Zyme L is an excellent grease degrader in sequencing batch reactors (SBR), wastewater treatment plants, equalization tanks, and food and egg processing plants. It can degrade a range of fatty acids such as oleic, steric, and palmitic as well as fish oils, triglycerides, milk, and animal fats. Qwik-Zyme L works best from pH 6-9 and from 45–140°F (8 to 60°C) and is formulated for aerobic treatment systems. For similar issues in anaerobic process, see Ana-Zyme G.

Dose Rates

Product Pairings

Follow up with Bug On A Rope for ongoing maintenance after the lift station is cleaned up.

Applications and Benefits

- Collection systems and lift stations

- Sequencing batch reactors (SBRs)

- Municipal plants

- Egg processing plants

- Reacts quickly

- Degrades fat, oil, and grease (FOG)

- Prevents foaming

- Cleans plants

- Easy to use

Case Studies

Manufacturer of Luxury Soaps Controls Fatty Acid Foaming

Challenge

High Lauric and Stearic Fatty Acids

Solution

Qwik-Zyme L, VitaStim Surfactants

Results

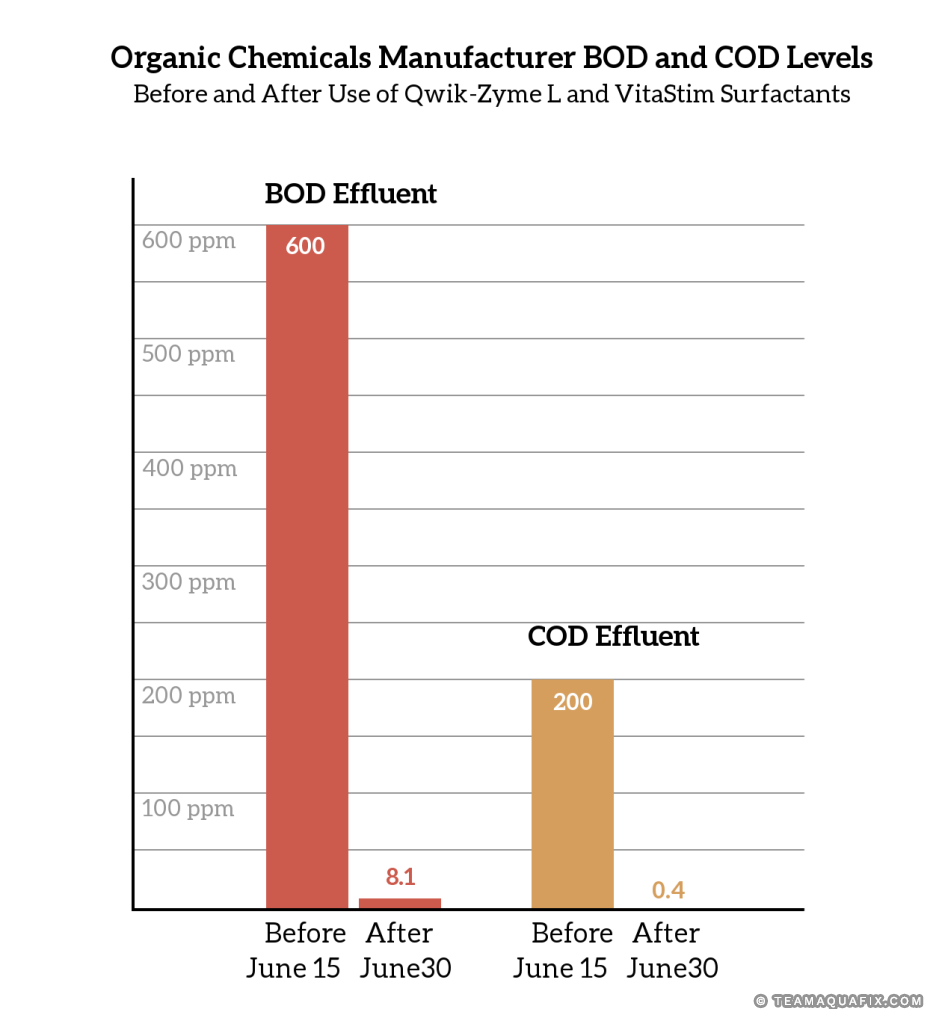

An organic chemical manufacturer in North Carolina contacted us about foam being generated in their treatment system. They use a series of two lagoons, with high aeration in the first lagoon to pretreat their waste stream before sending it to the municipal wastewater treatment plant. The waste stream has high concentrations of lauric and stearic acids which contribute to 600 ppm influent BOD and 200 ppm COD. The system was not achieving complete breakdown of these fatty acids as the waste stream moved quickly through the system. The operator began using VitaStim Surfactants to add new bacteria cultures which break-down fatty acids. This improvement was enough to make the customer happy, but we thought that adding our Qwik-Zyme L, a liquid biocatalyst product, would help break down the fatty acids even more quickly. The biocatalyst accelerated the process, which was a huge benefit in this waste stream with a short detention time. The combination of biocatalyst and bacteria brought the system’s effluent waste stream down to 8.1 ppm BOD and 0.4 ppm COD.

Municipal WWTP and Local Industry

System

Activated Sludge

Flow Rate

120,000 gallons per day

Background

The municipality upgraded their wastewater plant three years ago with fine bubble aeration. Immediately they began noticing a foot of foam on the basins and persistently higher effluent ammonia numbers. They traced the foaming issue down to a tannery in town. The tannery has an existing wastewater process of their own consisting of an equalization tank followed by aeration and a very simple DAF unit. To clean the fat, oil, and grease off hides the tannery uses surfactants, substances similar to soap in their make-up. We learned the cause of the issue in the municipal plant was that surfactants were passing through the tannery system undigested and then foaming when they hit the fine bubble diffusers at the municipal system. The tannery experimented with a number of surfactants to help stop the foaming but to no avail.

Solution

The solution was to breakdown the surfactants at the tannery’s treatment plant. We had them increase the holding time in their EQ tank to create anoxic conditions and then they added Qwik-Zyme L and Qwik-Zyme P to speed the breakdown of the grease and long-chain fatty acids. The process was further enhanced by adding Foam Buster to the aeration tank. Foam Buster’s micronutrient blend boosts the ability of native bacteria to degrade fatty acids and grease. The biocatalysts kicked off the surfactant degradation process and the native bacteria, with the help of Foam Buster, finished the process. Immediately, the city noticed 95% less foam and better settling. As the foam went away they also realized that the surfactants had been knocking out their nitrifiers. As the surfactants were no longer hitting them as they had before, nitrification improved and their effluent ammonia dropped. Now both the municipality and the tannery are happy.

Ryan S (FL) –

Helps get control of bulking filaments fast. Easy to use and effective.

Josh L (CO) –

Quick-Zyme L, Smart BOD, and ReBuild have helped our plant recover and run great through start up and shock while jetting lines. Operation of two SBRs is needed to accommodate the volume of decant from the digester. We run on the low end of the F:M ratio and these products help with that also.

Village of Westfield (WI) –

Began using these two products (Foam Buster & Qwik-Zyme L) one month ago to help reduce nocardia. Though I still need to waste more at the plant, I am seeing a benefit in phosphorous reduction it appears based on data.

Steven C. (PA) –

I was using Qwik Zyme L in conjunction with Foam Buster to attack a bad foam problem i had in the aeration process after a large upset. It was causing problems in the clarifiers and plugging the skimmers. I tried applying Sodium hypochlorite, to no avail. I did a little research and found that people were using the Qwik Zyme L paired with a couple other products and seeing very good results. So, i decided to try it, and am glad i did. I now keep at least 5 gallons on hand in case of another issue, so i can get a head start on it.

Kyle M. (CA) –

Our wastewater system was overflowing due to surfactants in the EQ and I decided to try the Qwikzyme L and Foam Buster based on the product descriptions on the website. Within 24 hours, the foam had been knocked down to manageable levels and within a week, it is completely gone. The Aquafix has emailed and called to be sure everything worked and made other suggestions to prevent future issues. I’m very impressed and will continue buying their products and utilize their expertise to manage our system.

Brad R. (TX) –

Nothing breaks down the grease in my lift stations like Qwik-Zyme L, it works quick and efficiently and saves money on vacuum services in the long run. Works really well with foambuster to keep foam levels at bay in my aeration basin.

Tyler S. (ME) –

Did a 60 day cycle and removed all the foam and filaments from our system.

Jeffery –

City of Pratt, WWTP in Kansas has been using this product routinely for the past two years. The City has an Activated Sludge process, specifically a U.S. Filter SBR system running two basins at 500 mgd. Prior to the Quick-Zyme product the winter months in our system were troublesome. With a build up of Filamentous bacteria due to high F.O.G. the resulting decants were bad due to poor settling. At a conference two years ago it was suggested to combat the filamentous we need to eliminate the food source (F.O.G). Quick-Zyme-L was specifically recommended. Since October of 2018 we have been dosing our basin’s through the cold months with excellent results. Reduction of TSS, and BOD in our final effluent was obvious. This resulting in reduced E-coli and Total Nitrogen. The staff at Aquafix has been easy, and prompt to work with. They will continue to receive the city’s business in the future.

Joe –

The cheese plant really dumped on us and the plant foamed up. We used a bit of Qwik-Zyme L and it ate it up. Incredible.

Jeff –

We had a bad Nocardia break out in our SBR and it was hard to control. We heard about the Qwik-Zyme L biocatalyst, and it worked. It was like Wow the foam went right down. Potent stuff.