Impact of Ana-Zyme G on Biogas Production in High F.O.G. Anaerobic Systems

by Dan McKeaton

Senior Researcher, Aquafix

Summary

- Ana-Zyme G is a product designed for anaerobic systems to break down fats and long chain fatty acids into short chain fatty acids.

- This study was designed to evaluate the impacts of Ana-Zyme G on biogas generation in a mesophilic dairy digester with the feed supplemented with 2% heavy whipping cream.

- Testing was run as a BMP style test at 35°C (95°F) run in the “Bioprocess Control: Gas Endeavor” system. Methane generation was tracked throughout the study.

- The study compared a 5-ppm, one-time addition of Ana-Zyme G to a control (no additives).

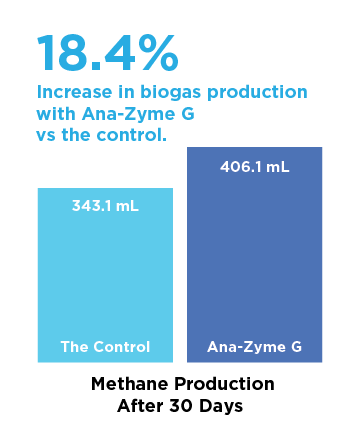

- An 18.4% increase in biogas production was observed with the addition of Ana-Zyme G.

Background

Many anaerobic digesters, especially in food related industries, receive exceptionally high levels of incoming fats, oils, and greases. Fats, oils, and greases (F.O.G.) can be an ideal food substrate for anaerobic digesters but, in many cases, can be the main limiter in the anaerobic digestion process. This could be the result of poor disintegration and hydrolysis of fats, or poor decomposition of long chain fatty acids. Because of this, Aquafix Inc. has studied the impact of Ana-Zyme G, a fat degrading biocatalyst, on anaerobic digestion.

The goal of this research has been to show improved biogas generation through the addition of Ana- Zyme G in high F.O.G. environments; as well as, show that Ana-Zyme G is unlikely to lead to increased digester acidification as a result of increased fatty acid production. Our previous study titled, “Impacts of Ana-Zyme G on the Anaerobic Digestion of Wastewater Fatty Acids,” confirmed that the addition of Ana-Zyme G decreased fatty acid content and did not lead to a decrease in pH, despite the digester feed being supplemented with 2% heavy whipping cream. This 2023 study specifically focuses on the impacts of Ana-Zyme G on biogas production, using a similar digester sludge, and feedstock to the previous study.

Methods

In order to measure the impacts of Ana-Zyme G on biogas production, we performed a BMP study using the “Gas Endeavor” system from “Bioprocess Control.” In this case, we used anaerobic reactors containing 400 mL of mixed digester sample. Samples were collected from a healthy, complete mixed, dairy digester. Two thirds of the bottle volume was filled with digester sludge. This sludge was starved for 1 week in anaerobic conditions at 35°C (95°F) prior to the study. The other third of the reactor volume was composite digester feed stock, supplemented with 2% heavy whipping cream to create a high F.O.G. environment. The reactors were continuously mixed throughout the study and maintained at 35°C (95°F). Methane production was continuously measured throughout the course of this study. All reactors were run in triplicate. Contact Aquafix if you have any questions about the methods used in this study.

Results

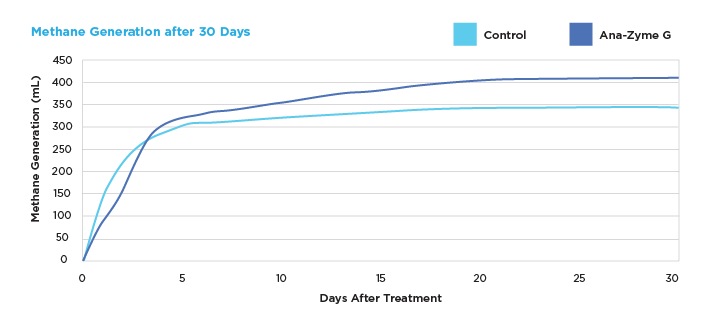

Figure 1. After 3 days, until the end of the study, we observed an increase in biogas production with the addition of Ana-Zyme G vs the control.

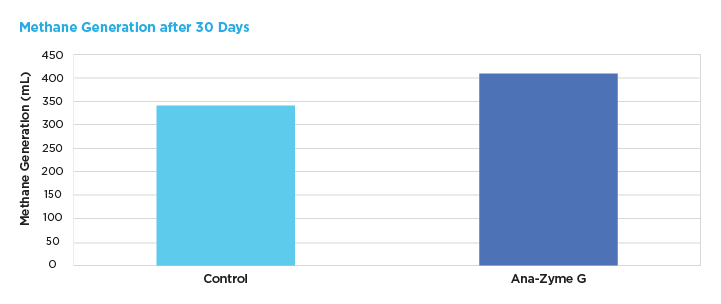

Figure 2. We observed a total increase in biogas production from 343.1 mL in our control, to 406.1 mL with the addition of Ana-Zyme G. This is an 18.4% increase in biogas production when comparing Ana-Zyme G to the control.

Background

In this study, we observed an 18.4% increase in methane production with the addition of Ana-Zyme G. In addition, even with 2% heavy whipping cream added to the feed, we did not observe any signs of a digester crash due to fatty acid overload which is consistent with our previous study. This study was most representative of a complete mixed, anaerobic system. However, complete mixed systems tend to be efficient at hydrolysis of fats, oils, and greases compared to less mixed systems, such as anaerobic lagoons. This may indicate Ana-Zyme G’s impacts on lagoon systems would be greater than in complete mixed systems. We did notice some decrease in biogas generation for the first 3 days of our study. While this may indicate a slight lag phase due to increased fatty acid production, none of our reactors appeared to be hindered by fatty acid loading past that point in the study. We are currently performing studies to expand our knowledge of anaerobic grease degradation in environments with even higher levels of F.O.G. loading. For any questions about future studies or new test results, please contact Aquafix Inc.