Sulfate-Reducing Bacteria and Their Relationship with Methanogens

Discouraging Their Growth For a Healthier Digester

by Dan McKeaton, Senior Researcher and Anaerobic Specialist

Sulfate-reducing bacteria (SRB) are the main villains of the anaerobic digestion process, taking valuable carbon substrate and using it to produce the dreaded, corrosive, and hazardous hydrogen sulfide! But why do these bacteria grow in anaerobic digesters so often? Do they cause problems because they are competitive with other anaerobic microbes? How can we discourage their growth for a healthier digester, less corrosion on digester components, and higher quality biogas?

About SRB

SRB use sulfates as their terminal electron acceptor for anaerobic respiration (aerobic organisms like us usually use oxygen as a terminal electron acceptor, for example). Therefore, the development of SRB is often limited to and directly tied to how much sulfate is entering a digester. In our lab, we’ve completed numerous studies on hydrogen sulfide, and we supplement our feed with sulfates to equip SRB with the ability to compete with other microbes without completely taking over our systems. The higher the sulfate content, the more efficiently these H2S producers compete for organic carbon. If sulfate levels are high enough, SRB can grow to such a degree that they begin to starve out healthy methanogens.

Typically SRB compete more directly with hydrogenotrophic methanogens compared to other methane producers, as hydrogen is often limiting for these species. SRB in these cases can stunt diversity in anaerobic systems, making them more susceptible to upsets. However, in most systems sulfate levels are not high enough for this to take place. Still, SRB usually make up a small but sizable portion of the anaerobic biomass. In most cases, methane production is often unhindered by the existence of SRB and an anaerobic digester can still produce respectable methane. Regardless, hydrogen sulfide often makes up as much as 1000-2000ppm of the biogas produced, which is still a major threat to equipment via corrosion and a major safety concern for confined spaces. Sulfides also create highly unpleasant odors, even in miniscule concentrations, and therefore can also impact local communities and plant operators. Because of these potential issues, controlling the production of hydrogen sulfide is often essential to anaerobic digester operations.

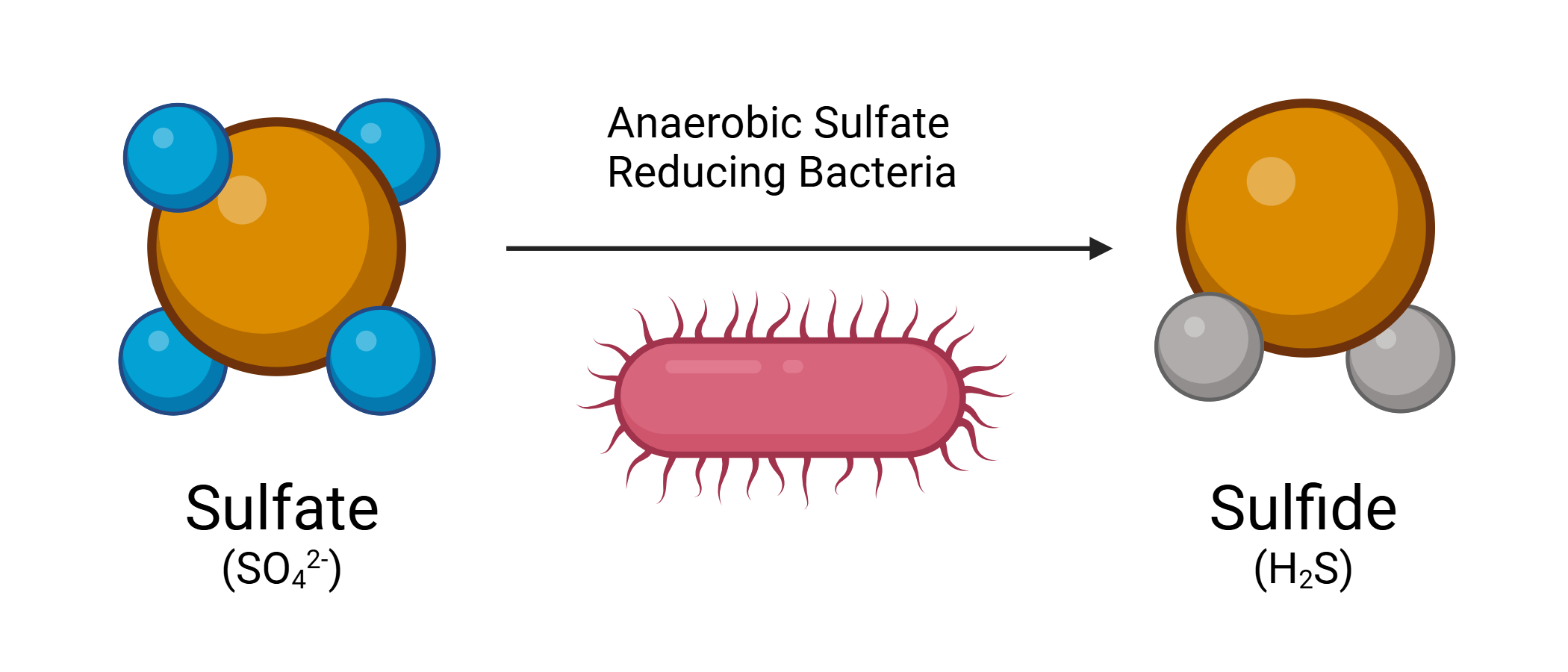

Figure 1. This diagram shows how SRBs can turn Sulfate (S₄O²⁻) into Sulfide (H₂S). Created with Biorender.com.

Finding Solutions

So how do we control this hydrogen sulfide production or hinder the growth of sulfate-reducing microbes? There are currently multiple approaches available. The most standard option is the supplementation of ferric chloride. Ferric chloride reacts to precipitate sulfates present in digesters. This prevents SRB from using sulfates for respiration. Systems with higher levels of metals often have far fewer challenges with hydrogen sulfide purely because of precipitation with sulfate. However, this can limit the bioavailability of metals, causing micronutrient deficiency. Therefore, supplementing with excess ferric chloride is often necessary to avoid removing other soluble micronutrients in a system.

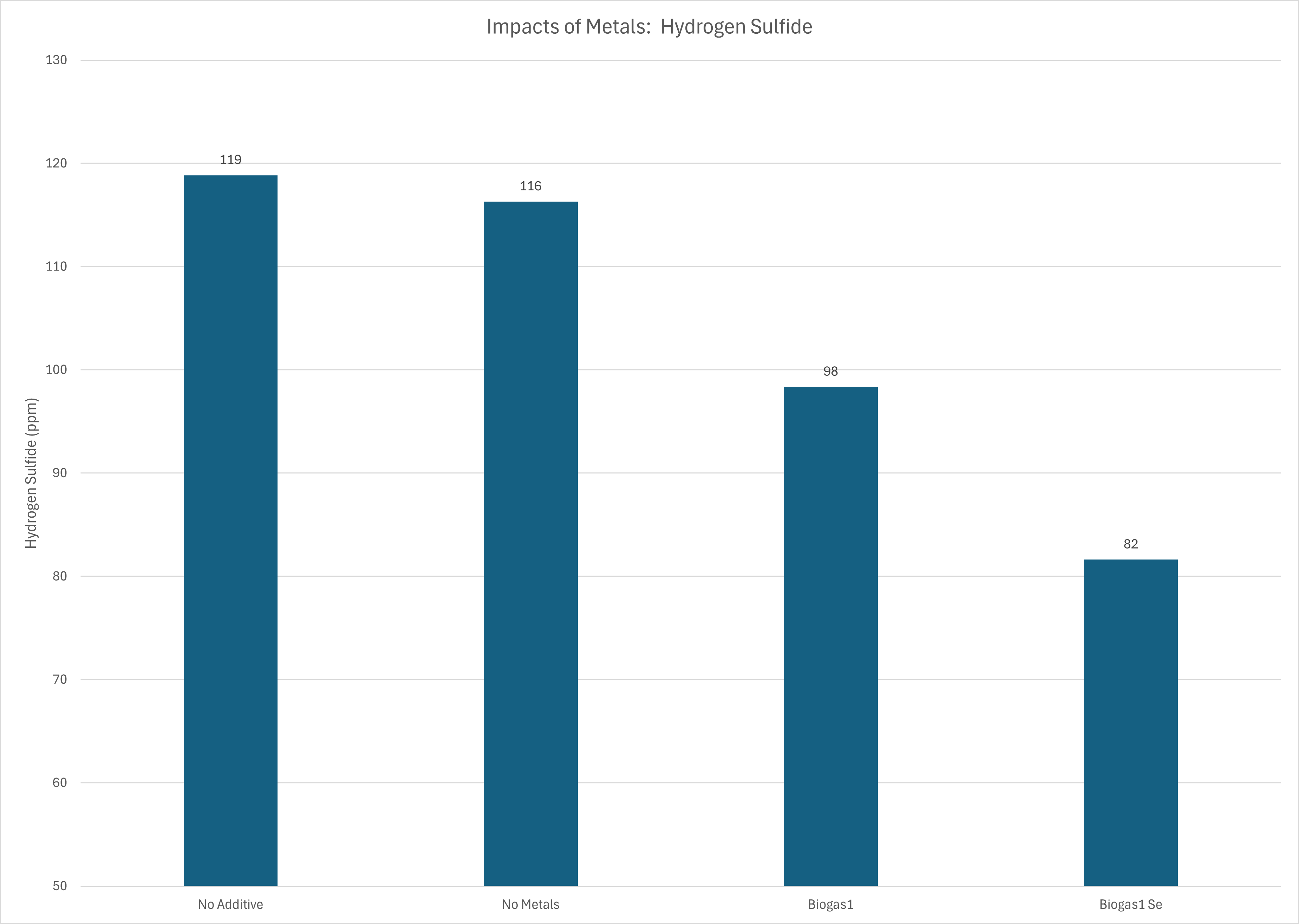

Figure 2. This diagram shows a general decrease in sulfide production with the addition of Biogas1 as a metals supplement. However, we observed better results with the addition of selenium to our Biogas1 blend. Selenium was added at a dose rate of about 2 ppb.

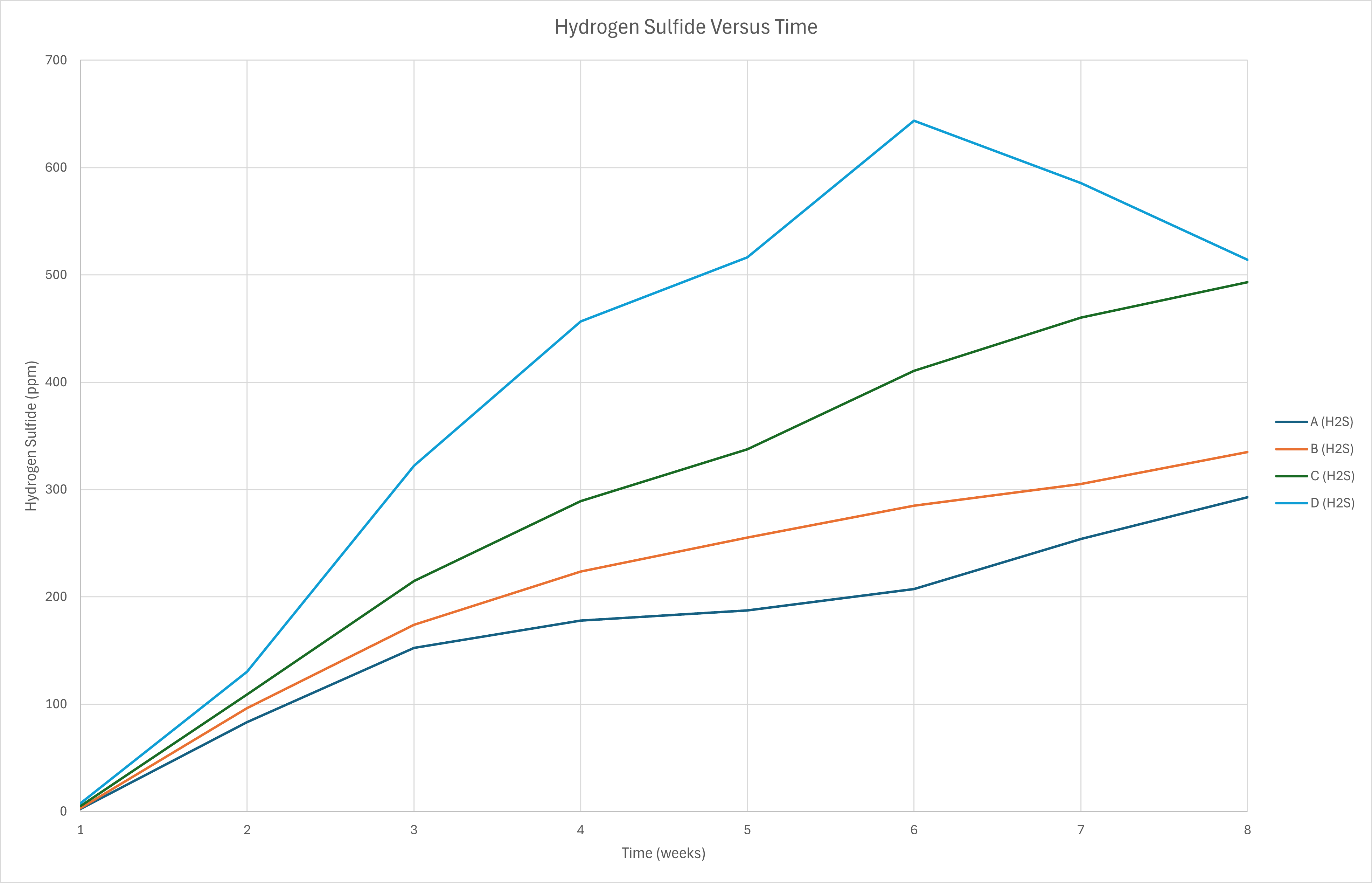

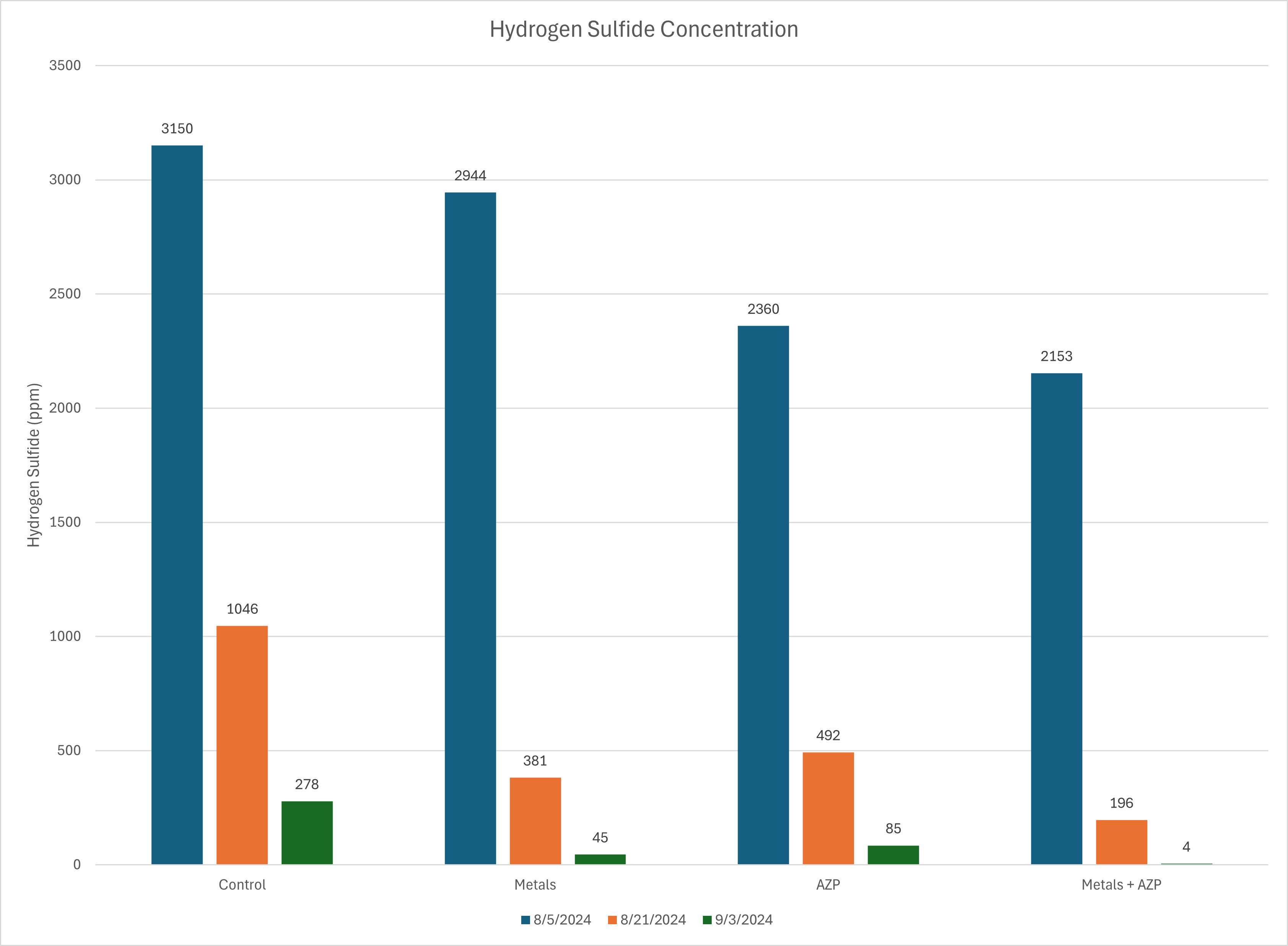

Several other approaches have been shown to have success in controlling the production of hydrogen sulfide, as well. Supplementation of excess molybdenum may inhibit SRB leading to reduced sulfide production. We have also observed some impacts on sulfur production from the addition of selenium, specifically even in exceptionally low dose rates (Figure 2). These approaches often should be considered on a site-by-site basis as results may depend on the water chemistry of the site, or the microbial population in a digester. Other control methods are also feasible in some cases, such as operating with a higher solids retention time to favor methanogens which are slow growers (Figure 3). We’ve also experienced success in several cases with the supplementation of Ana-Zyme P (Figure 4) and we are currently performing research on the impacts of enzyme supplementation on hydrogen sulfide formation to better understand this phenomenon.

Figure 3. In the diagram above, we operated digester A at a 45-day SRT, B at a 35-day SRT, C at a 25-day SRT, and D at a 15-day SRT. In general, decreasing SRT seemed to clearly favor the growth of SRB.

Figure 4. This diagram shows reduction of hydrogen sulfide levels at 3 different time points in a BMP study for a digester. We also observed a decrease with the supplementation of Biogas: Spectrum (metals) which illustrates how general metals supplementation can be effective at reducing sulfides.

Products to Help Anaerobic Digesters

Ana-Zyme P

- Speeds the breakdown of proteins into amino acids

- Lowers levels of volatile solids and improves biological methane potential

- Works between 59 -140°F (15-45°C) and between pH 6.0 and 8.5

BioGas Spectrum

- Macro levels of Iron, Cobalt, Nickel, Selenium, and Molybdenum in a bioavailable form that enhances microbial metabolism.

- Balances Anerobic Processes

- Reduces Sludge production

About the Author

Dan McKeaton is a senior researcher and anaerobic digestion specialist at Aquafix Inc. He has performed wastewater research for over 10 years and has presented his work at WEFTEC’s technical symposium on the impacts of quaternary ammonium cation disinfectants on biological wastewater treatment. Currently, Dan is responsible for designing and executing our studies on anaerobic digestion and developing anaerobic products with a current focus on controlling hydrogen sulfide production in anaerobic digesters.