Winery expansion has been growing fast over the past decade, and the high demand for fermented grapes has put a toll on winery wastewater treatment. Their treatment plants already have trouble keeping a stable operation as their load variability changes so often, depending on production stage. The plant’s bacteria are either in feast or famine mode, which causes upsets that lead to sludge bulking and TSS/BOD violations. With tightening grips on environmental compliance and the lack of water and manpower, wineries are struggling to operate an efficient and effective wastewater treatment process.

All industry wastewater plants have variable loads, but the waste from winery production stages are so vast in difference, it sets off upsets. During the racking stage BOD can be 10 times as much as municipal wastewater, then drop to almost nothing then after. The food to microorganism ratio change is so violent; the bugs simply cannot keep up. The wastewater plant struggles from being either becomes too small for such solids or too big for such little food.

Winery Wastewater Treatment Plants Are Outdated

Small scale wineries only have septic and leach field systems that inevitably clog after high solid stages. Wastewater pond systems are most commonly found in wineries, but fail to break down BOD and major fruit contaminants like tannins. Today wineries are being forced to upgrade to bioreactors or activated sludge plants, which call for more labor and maintenance that they don’t have.

Aquafix is Researching Ways to Promote Winery Efficiency

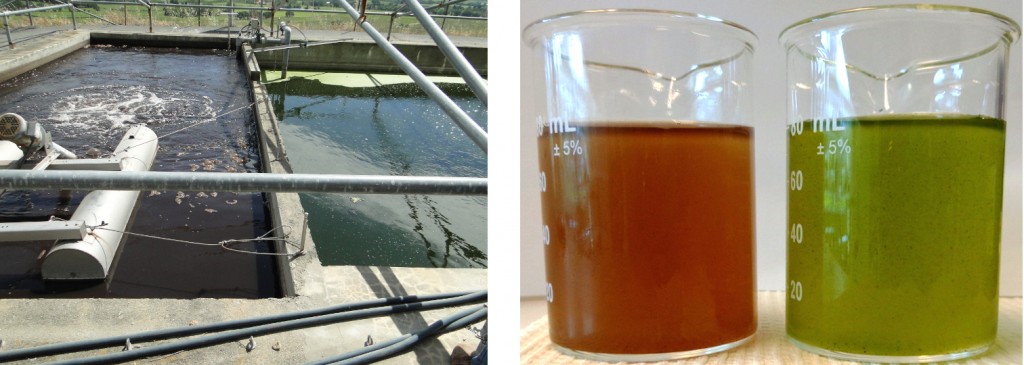

Below you will see our friends in Napa Valley had major issues at control BOD and tannin levels in their wastewater plant. We helped out by introducing select bacterial cultures along with micronutrients and powerful biostimulants to correct the issue. The tank on the left is an aeration basin filled with tannins and contaminants, this is where our products are introduce and work. The tank on the right is a reaeration basin, where you can already see a healthier water color. The beakers show a close up comparison between both tanks.

Based on this solution and many others, Aquafix is planning on launching a brand new product to benefit winery wastewater treatment. This product will stimulant the bacteria to fully breakdown solids and lower BOD, TSS and tannins, while also keeping the bacteria thriving in low food conditions. This will ultimately allow for less labor and maintenance with the ability to reuse water, pushing forward with the idea of a greener more sustainable winery.

**Update:

Aquafix has launched its VitaStim Winery to treat the multiple issues with winery wastewater treatment plants. This product was developed under close studies with the variable wastewater from vineyards that has cause upsets, environmental permit breaks, and more maintenance time. Take a look at the link or give us a call for more information.

A 200000-bottle product winery wastewater and recycle system calculation and need

A 200,000 bottles product winery needs to construct a septic and wastewater recycling systep

We need basic information about the plant