Ana-Zyme G: Impact on Anaerobic Digestion of Wastewater Fatty Acids

by Justin Hall, Project Specialist, University of Wisconsin-Stevens Point

Summary

Wisconsin Institute for Sustainable Technology at UW Stevens Point conducted a study to evaluate impacts of

Ana-Zyme G on fatty acids in dairy wastewater.

Ana-Zyme G was added as a single dose at 1 ppm at the start of testing. The addition of 1 ppm Ana-Zyme G led to a 34% reduction in total fatty acids by the end of the test. Levels of short-chain fatty acids also decreased with the addition of Ana-Zyme G, suggesting breakdown of grease did not contribute to overabundance of short-chain fatty acids.

Objective

This study was designed to determine if Ana-Zyme G (AZG) is effective in assisting with the degradation of fats and fatty acids from cream waste in an anaerobic system. This study was completed at the Wisconsin Institute for Sustainable Technology (WIST) located within the University of Wisconsin – Stevens Point. Five different fat samples were tested including butter, coconut oil, lard, a field sample, and a composite of butter, lard, and coconut oil. The Aquafix GreaseZilla biocatalyst was also compared against a competitor’s product.

Background

A wastewater facility for dairy waste processing was having difficulties maintaining gas production and granular sludge in their mesophilic UASB due to large dumps of cream occasionally entering their wastewater system. Spills could be over 1000 gallons of undiluted cream. This system has an average flow rate of 350,000 GPD, with an average incoming COD of approximately 8300 ppm. The wastewater is digested by two 75,000 Gallon mesophilic UASB reactors. Samples of granular sludge and incoming cream waste were collected to determine how Ana-Zyme G influenced fatty acid degradation.

Methods

Anaerobic digestion testing was run by UW-Oshkosh Environmental Research and Innovation Center. This testing was run in unmixed anaerobic reactors at 38°C. These reactors were seeded with 1 liter of mixed UASB sample containing 6% solids. Reactors were fed an additional 30 grams (approximately 30 mL) of provided cream wastewater. Ana-Zyme G was fed into the reactors at 0 (controls), 1 ppm, 10 ppm, and 20 ppm per reactor volume. Reactors were run in triplicate. Samples were collected by UW-Oshkosh at the end of 28 days and sent to UW-Stevens Point for long and short-chain fatty acid analysis to measure the overall degradation of fatty acids present in the reactors. Results were analyzed by Aquafix Laboratories.

Notes on Fatty Acid Notion and Degradation

Note: in this paper, fatty acids are referred to both by their specific names, and by the number of carbon units within them. For example, a fatty acid with 18 carbon molecules in its chain will appear both as Stearic acid and C18.

Note: in this paper, fatty acids are referred to both by their specific names, and by the number of carbon units within them. For example, a fatty acid with 18 carbon molecules in its chain will appear both as Stearic acid and C18.

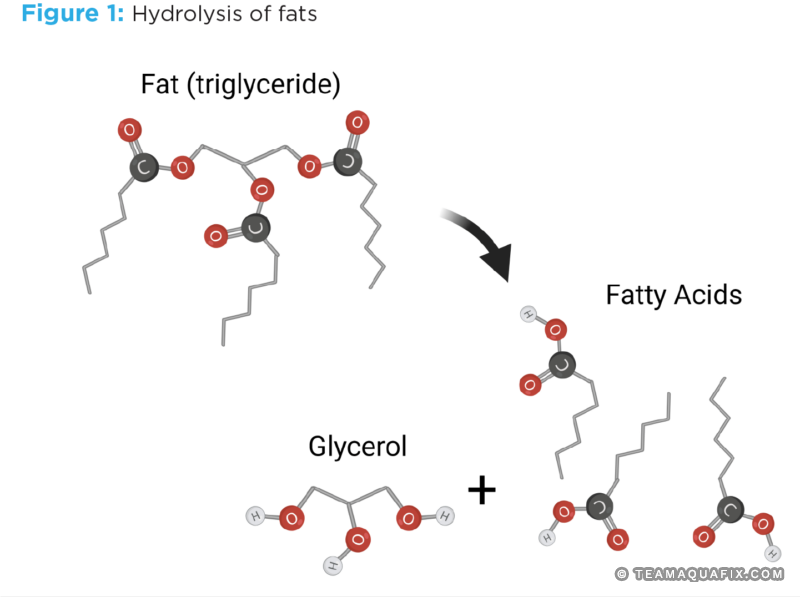

Fat molecules are typically made up of a glycerin molecule covalently bonded to 3 fatty acid chains. These fatty acids are initially detached from the glycerin molecule through a process called hydrolysis. Fatty acids have the potential to be an excellent source of methane generation in anaerobic systems if they can be converted to acetic acid, the preferred substrate for methane generation. Assuming a digester has a healthy population of methanogens, breaking down fatty acids often is a rate limiting step for methane production.

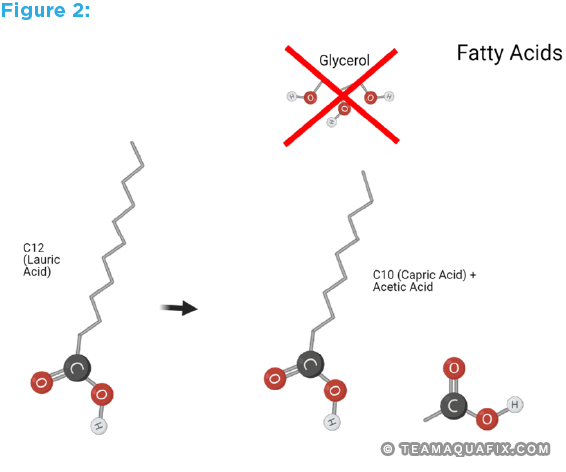

Hydrolysis generally produces 3 separate long chain fatty acids, such as C18 (Stearic acid). This is illustrated in Figure 1 above. Fatty acids chains are almost always broken down in units of 2 through a process called β-Oxidation, as seen in Figure 2. For example, C18 would become C16, with 1 C2 (Acetate) produced through the process and acting as food for methanogens. C16 would then be broken down to C14 and so on until the chain is completely converted to C2 (Acetate) chains.

Results

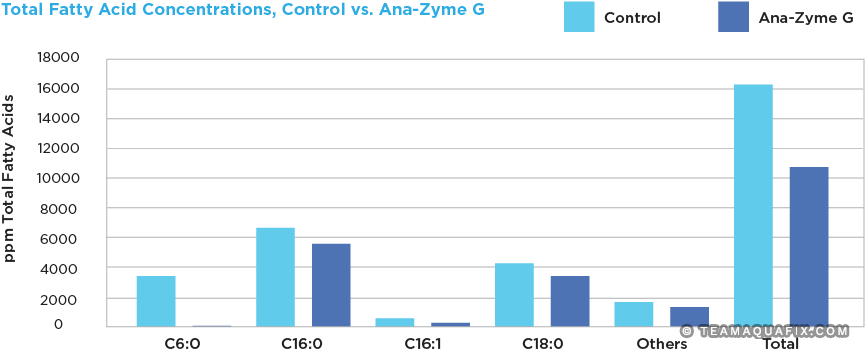

Figure 3 (above)

Individual fatty acid species concentrations in our control and with Ana-Zyme G (AZG) at the end of our study. Fatty acid chains that are not listed were below detection limit for both the control and 1 ppm Ana-Zyme G.

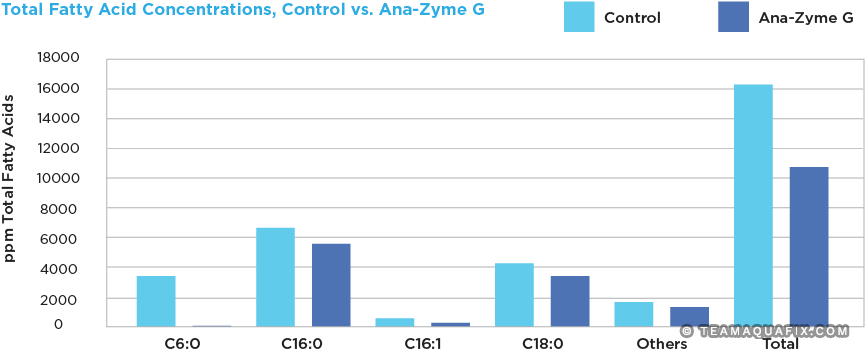

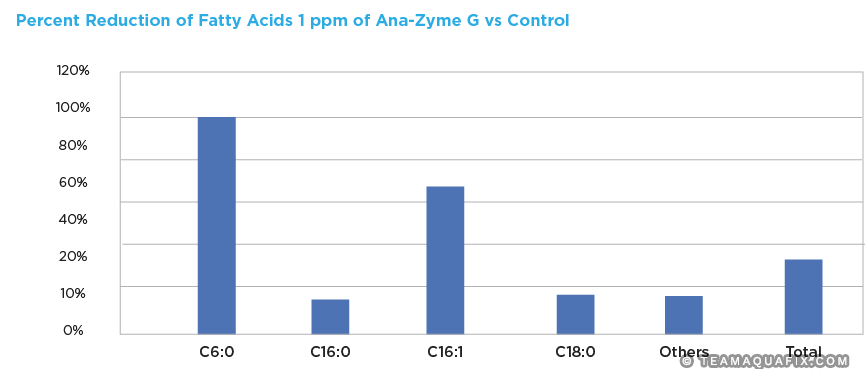

Figure 4 (above)

Percent reduction of fatty acids with Ana-Zyme G relative to our control. We observed an 100% reduction in fatty acids levels with Ana-Zyme G in our 6-carbon fatty acid (carboxylic acid), and 68% reduction in our 16-carbon fatty acid (palmitoleic acid). Our total reduction of fatty acids was increased 34% relative to our control with 1 ppm of added Ana-Zyme G.

Conclusion

Overall, we noticed a 34% reduction (Figure 4) in fatty acid concentration with the addition of one

dose of Ana-Zyme G versus the control. In addition, no evidence was observed of an increase in short-chain fatty acids present in our reactors with the addition of Ana-Zyme G. This shows that while Ana-Zyme G does reduce the prevalence of long-chain fatty acids as intended, it did not appear to contribute to an overabundance of short-chain fatty acids (Figure 3). This illustrates that Ana-Zyme G is safe and effective at reducing levels of fatty acids in anaerobic digesters in systems with high FOG loading, without leading to short-chain fatty acid buildup which could contribute to a decrease in digester pH. Reactor pH was measured at the end of the study, and we noted the pH average in our reactors with 1 ppm Ana-Zyme G were 7.1 versus the Control average pH of 6.9 (Appendix 2). Higher doses of Ana-Zyme G only led to slight improvements in total fatty acid concentrations versus 1 ppm in this study (Appendix 1).