Ana-Zyme P: Anaerobic Lagoon Methane Generation in Meat Packing Plant

by Justin Hall, Project Specialist, University of Wisconsin-Stevens Point

Summary

Wisconsin Institute for Sustainable Technology at UW Stevens Point conducted a study to evaluate impacts of Ana-Zyme P on anaerobic lagoon methane generation in a meat packing plant.

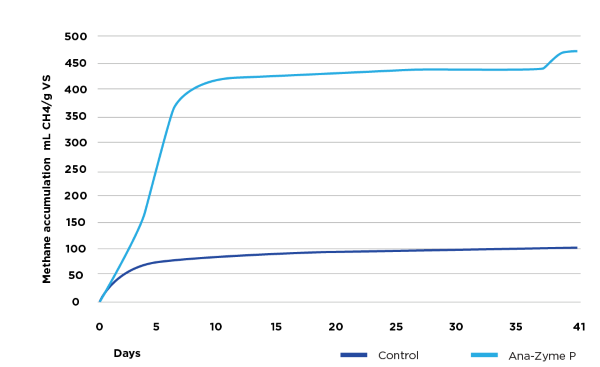

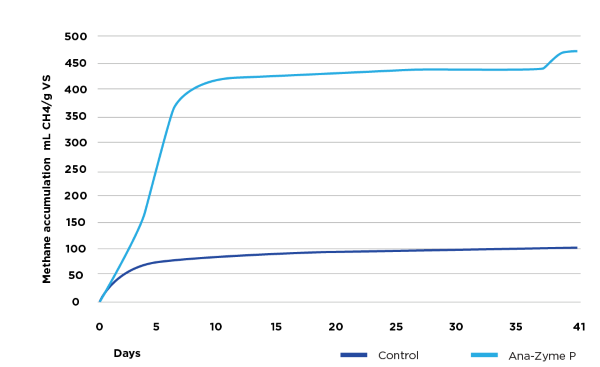

Ana-Zyme P is a product designed for anaerobic systems to break down complex proteins into free amino acids. This study was designed to evaluate the impacts of Ana-Zyme P on biogas generation in a mesophilic anaerobic laggon from a meat processing plant. Samples from the lagoon were used to run a BMP test comparing methane generation with a one-time addition of 5 ppm Ana-Zyme P verses a control. The reactors with added Ana-Zyme P accumulated 4.6x more biogas over a 40 day period versus those without.

Background

Fats and carbohydrates tend to be the preferred feed substrate in anaerobic digesters due to their high BOD content, and low nitrogen requirements of anaerobic bacteria. This means that anaerobic hydrolysis tends to favor the breakdown of fats and complex sugars over the degradation of protein. However, proteins break down to generate valuable amino acids which can be used to greatly accelerate enzyme production. This improves anaerobic efficiency. When free amino acids are absent, generally, anaerobic bacteria need to produce them using simple carbon substrates and ammonia. This process takes additional metabolic steps and wastes carbon making the process inefficient.

This idea led us to study the impacts of Ana-Zyme P in an anaerobic lagoon to determine if the addition of this product could lead to improvements in biogas generation by breaking down proteins into free amino acids. In this study, we decided to use samples from an anaerobic meat processing system due to its high protein content.

The anaerobic meat processing system we used for this study has three mesophilic 8-million-gallon anaerobic ponds as the first stage in their treatment process. Daily flows fluctuate between 150,000 and 500,000 GPD and incoming COD between 1500-7200 mg/l. The ponds are covered with a geomembrane cover. The operators of the system were interested in finding ways to optimize their anaerobic process efficiency.

Objective

To determine the effects of Ana-Zyme P on methane generation and solids destruction in an anaerobic lagoon for a meat processor.

Methods

In this study, we used a standard BMP test to measure methane generation comparing a control (no additives aside from seed sludge and digester feed) to a reactor with 5 ppm Ana-Zyme P as a supplement. Reactors in this study were run in triplicate with 2-liter anaerobic reactors. Temperature was maintained at 39°C for the duration of the testing. Anaerobic reactors were fed a blend of 450 mL of feed stock and 1350 mL of anaerobic lagoon composite samples. These volumes were used to be representative of the sample site. The digester samples used were analyzed for micronutrient content which showed no major micronutrient deficiency in the anaerobic samples.

Discussion and Conclusions

In this test, we observed a 4.6x increase in methane generation with the addition of Ana-Zyme P verses our control. This strongly suggests that liberating free amino acids from the protein present in meat processing wastewater can help improve methane generation in a meat processing lagoon. In this case, it is most likely an increase in free amino acids led to more efficient protein production in the anaerobic reactors. In particular, the production of enzymes by anaerobic bacteria may have been accelerated due to an abundance of amino acids. This increase in enzyme production can lead to more efficient degradation of many substrates used for methane generation in anaerobic lagoons. We observed the most pronounced increase in methane generation in the first 10 days of our BMP test. This rapid increase in biogas generation is consistent with what would be expected in a system with greater enzyme production. We also observed an interesting small jump in methane production between 38 and 39 days in our testing. This could be the result of increased acid generation from remaining free amino acids present or from greater methane production from hydrogenotrophic methanogens in an environment with elevated levels of free amino acids.

Future studies are required for a better understanding of the impacts of Ana-Zyme P in a wider variety of applications. However, it does appear that Ana-Zyme P could be used to improve methane production efficiency in anaerobic meat processing lagoons.

Methane Accumulation in Wastewater Lagoons

Figure 1 (above)

We observed cumulative methane generation of 3 mL CH4/g VS with our control verses 13 mL CH4/g VS with Ana-Zyme P. This reflects a 3.3x increase in methane production in our reactors with the addition of Ana-Zyme P. The reactor with Ana-Zyme P did have a somewhat longer acclimation period before its first methane production spike versus the control. However, methane production was sustained for 56 days with Ana-Zyme P versus 21 days with the control. It is possible that methane production would have continued with Ana-Zyme P past the 56-day duration of the test.