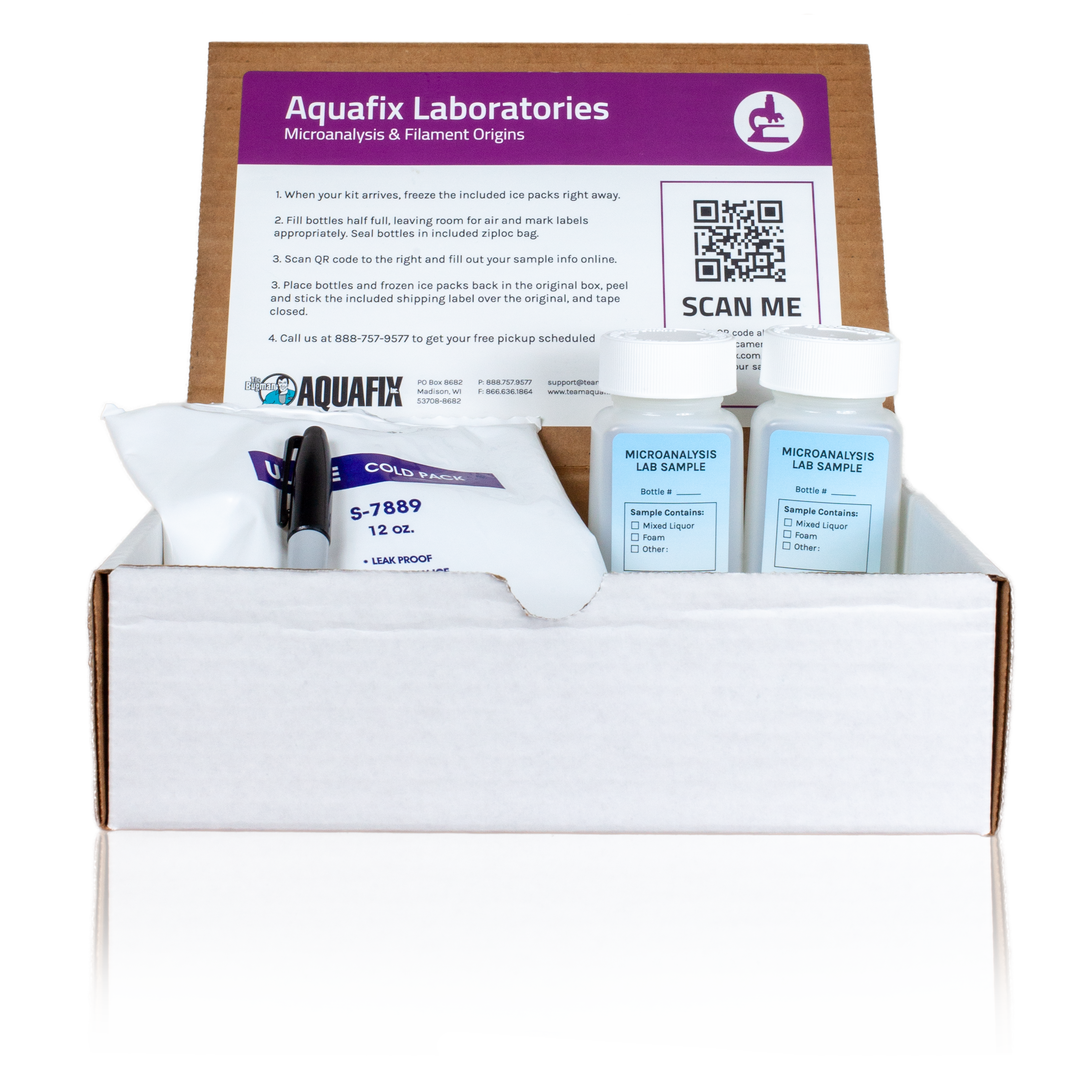

Filamentous Foaming 101

An overview the common causes of filamentous foaming.

by Melissa John, Aquafix Research Scientist

Foaming is a common problem in wastewater treatment and can occur in multiple processes (i.e., clarifier, aeration basin, aerobic digester) within a plant. Not only can foaming create hazardous working conditions for operators, but it also hinders the performance of treatment plants. Though foaming can be caused by an assortment of issues, we will cover the two most common foaming filaments, Nocardia-like Organism (NALO) and Microthrix parvicella.

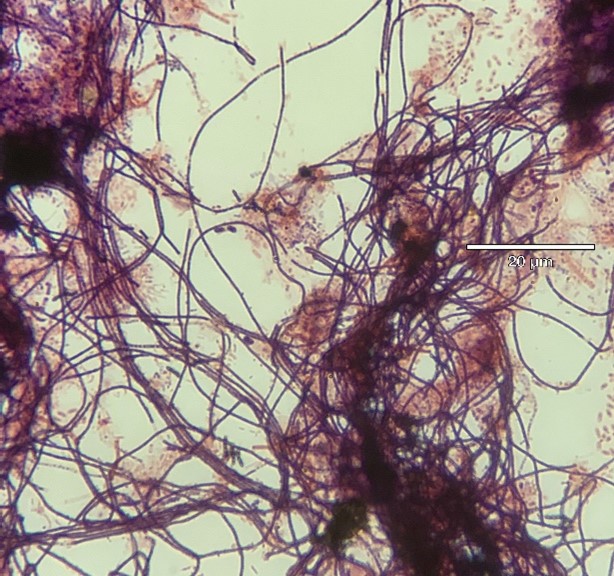

These filaments typically produce a thick, brown, stable foam; however, this observation is not enough information to identify these filaments as the cause of the foaming. So, what do these filaments look like with the use of microscopy? Both filaments are easily identifiable under the microscope because of their unique characteristics. NALO has a characteristic known as true branching. This is when the branches of the filament are still connected to the main trichome, rather than a trichome breakage within the sheath of the trichome, and like the name, true branching implies this filament looks like a tree branch. Lastly, NALO also stains Gram positive and sometimes contains Neisser negative granules. M. parvicella has a very distinctive, spaghetti-like appearance, which often tangles. This filament stains strongly gram positive and contains Neisser positive granules, as well.

1000x (m) Gram Stain of NALO.

So, how are these filaments occurring in treatment plants? Well, both filaments thrive in environments that receive high inputs of fats, oils, and greases (FOG). FOG environments allow them to outcompete flocculating bacteria because these filaments have a hydrophobic structure, causing them to float to the surface of the water, making these long chain fatty acids (FOG) closer in proximity and, therefore, more usable and accessible for the filaments rather than the bacteria. Along with these filaments having more consistent contact with the lipids, they have a cell structure with high fat content, which allows them to be able to degrade lipids with less energy. While this is one reason for these filaments being in your system, M. parvicella also prefers colder temperatures (below 65º F), so this is a common problem for plants transitioning into the winter season. Additionally, NALO prefers plants with a higher sludge age because NALO is a slow growing filament and requires a longer sludge age to develop and proliferate.

1000x (m) Gram Stain of M. parvicella.

Now that we have addressed why they are in the plant, let’s talk about why they are causing the foam. In high abundances M. parvicella forms tangled mats because of its structural characteristics. These mats end up floating because of reduced surface tension from the high concentration of low-density fats present in their cell walls. Since this mat is on the surface of an aerated system, it traps the air getting diffused from the system, causing foam. The process of NALO is similar to the foaming process of M. parvicella, as NALO forms tangled mats due to their branching structure. They also have a low-density fatty membrane along with a biosurfactant that covers them, allowing this filament to produce a foam.

There are many ways to remedy the foaming caused by these filaments, both mechanically and biologically, though both treatments combined are ideal for the best treatment. One approach is the physical removal of grease because if you remove the food source for these filaments, they will not have the ability to outcompete flocculating bacteria. Both filaments are associated with longer sludge ages, so an increase in wasting will lower the sludge age and balance the F:M ratio, which will aid in the remedy of these filaments. Since both filaments tend to form mats and float to the surface, vacuuming off the foam to an offsite location can speed up treatment since they are typically concentrated in the foam, though this is a temporary solution. The best way to treat these filaments is through these mechanical methods mixed with biological correction. At Aquafix our foaming filament products address and fix the biological problems. For these filaments we recommend the use of Qwik-Zyme L and Foam Buster. Qwik-Zyme L incorporates fat-degrading biocatalysts, which break down the long chain fatty acids into simple short chain fatty acids. Since these fatty acids are broken down, it cuts off the filament’s food source. Foam Buster is recommended to be used in tandem with Qwik-Zyme L as this provides the flocculating bacteria proteins, amino acids, and micronutrients to aid them in breaking down grease and allows them to outcompete the filaments.

Filamentous Foaming Solutions

Qwik-Zyme L

- Mitigate foaming and FOG filament outbreaks

- Removes oil scum in clarifiers and aeration basins

- Improves BOD removal and effluent TSS caused by high incoming FOG

Foam Buster

- Digests short chain fatty acids and the by-products of grease degradation

- Provides key nutrients and stimulants

- Safe and easy to use

About the Author

Melissa John is a Research Scientist for Aquafix and holds a bachelor’s in environmental sciences. Melissa is the newest member to the Aquafix lab team and has been familiarizing herself to wastewater microscopy.