From Micro to Macro

Scaling Up Digester

Startup Strategies

Insights from Our Miniature Digester Study

by Dan McKeaton, Director of Wastewater Education

This February, we began our first 2L digester study to assess new variations of our anaerobic food supplement. While this is obviously not exactly the same as starting up a full-scale digester, the combination of minor operational issues, unusual pH behaviors, and unexpected sludge volcanos were a bit of an eye-opener to the digester startup experience. In this blog, my intent is to share some of our operational findings from our first study and tie this into full scale digester startup decisions relating to digester seed sludge and startup behavior.

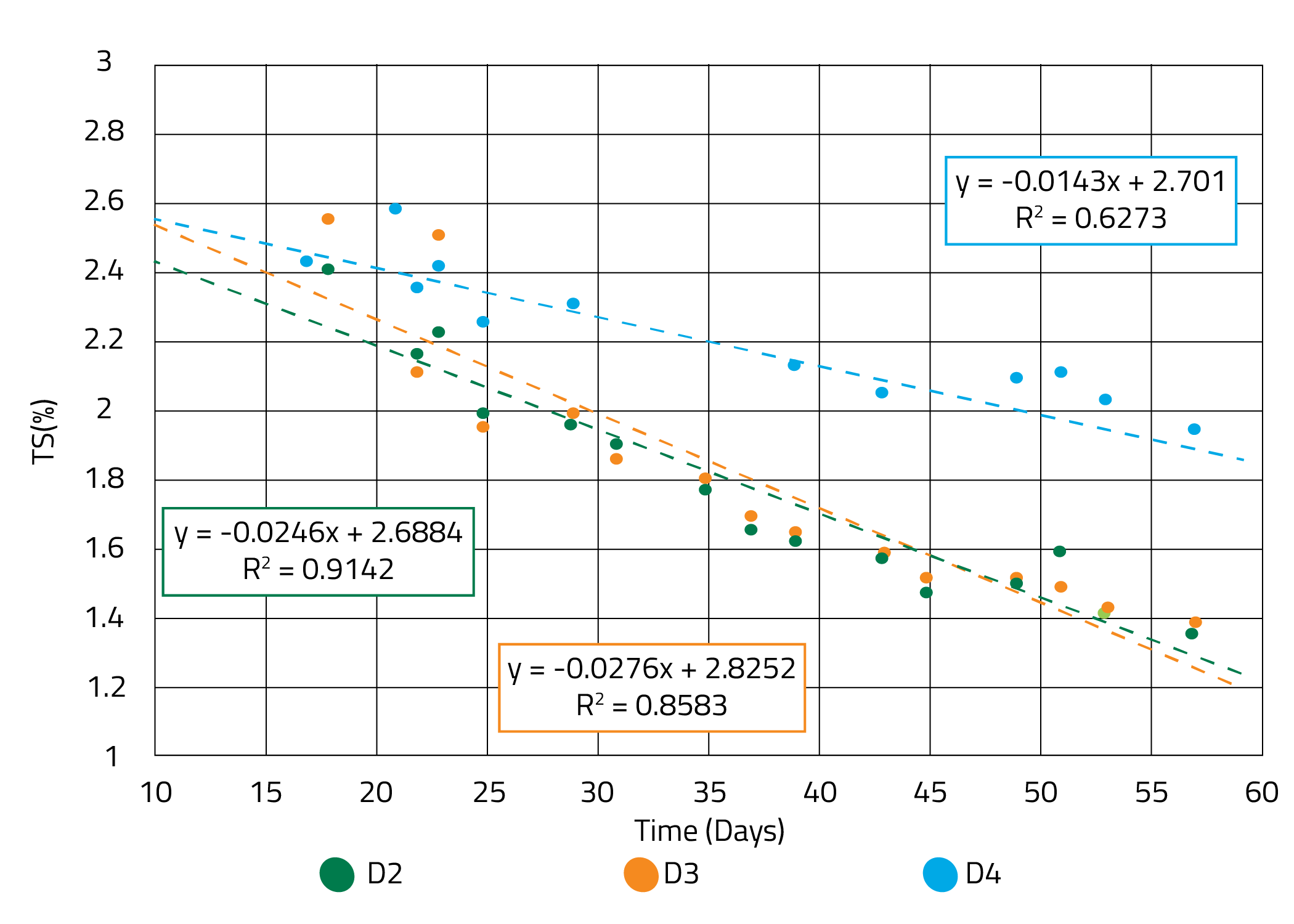

Total Solids Versus Time

Figure 1. Over the course of this study, TS content decreased substantially. We noticed digester 2 (D2) did a little better job maintaining solids than our other feed options but this did not result in improved digester performance by any other metrics.

To seed our digesters, we made a diverse composite sludge which was a combination of dairy manure digester sludge, creamery digester sludge, and municipal digester sludge from active, relatively healthy digesters. Our digesters were completely mixed with overhead mixers and fed daily for about 3 months. Luckily, it is very easy to seed a 2-liter digester with sludge as we didn’t require an enormous sludge truck. Because of this, we were able to start our digester off easily at 3% solids which helps to prevent upsets from overfeeding a new digester. Typically, in a field startup, using a healthy sludge from a similar seed is the best practice and essentially the digester should be seeded with as much solids as possible if a full 2-3% solids is not possible. More healthy sludge means a lot less growth time for methanogens which are especially slow-growing bacteria. Many

digesters rely on cow manure as a startup sludge which can work well but will have a substantially longer startup speed than a healthy sludge from a similar digester. As digester startups can range from being as short as 1-2 months to as long as a year, representative feed stocks can easily save you months on total startup time.

To seed our digesters, we made a diverse composite sludge which was a combination of dairy manure digester sludge, creamery digester sludge, and municipal digester sludge from active, relatively healthy digesters. Our digesters were completely mixed with overhead mixers and fed daily for about 3 months. Luckly, it is very easy to seed a 2-liter digester with sludge as we didn’t require an enormous sludge truck. Because of this, we were able to start our digester off easily at 3% solids which helps to prevent upsets from overfeeding a new digester. Typically, in a field startup, using a healthy sludge from a similar seed is the best practice and essentially the digester should be seeded with as much solids as possible if a full 2-3% solids is not possible. More healthy sludge means a lot less growth time for methanogens which are especially slow-growing bacteria. Many digesters rely on cow manure as a startup sludge which can work well but will have a substantially longer startup speed than a healthy sludge from a similar digester. As digester startups can range from being as short as 1-2 months to as long as a year, representative feed stocks can easily save you months on total startup time.

Once our digesters were in operation, we had some questions regarding what SRT ( Solids Retention Time) was required to maintain solids relatively well given our feed was a liquid feed substrate. We actually found using a liquid feed even with a 50-day SRT, we were still gradually losing solids throughout the duration of the study (Figure 1). This did not seem to correlate in any way with reduced digester performance even when total solids were approaching 1.3%. That being said, the loss of solids likely wasn’t related to a loss of methanogens or other anaerobic bacteria and was more representative of washing out inert substrates from the seed sludge. We likely will be solving this problem in the future by reducing the mixing speed or turning the mixers off prior to sludge sampling to prevent as much loss of solids during the feed as possible. Alternatively, we could add a relatively inert solids supplement to maintain our total solids concentration in the digester which would make this a bit more representative of a full-scale system. A little bit of dairy manure added to the feed to maintain solids might be a great fit for this application as well, but in our case, we want to avoid introducing too many nutrients because we want 100% of the feed to be introduced by our food supplements. Generally, co-digestion with other food substrates will improve digester bacterial diversity which tends to lead to more efficient stable digester operation, but our study was intended to be more of a worst-case scenario.

This study is nearly complete at this time and we’ll likely be releasing more comprehensive results of this study later on this year. Please reach out with any questions about this study, results, or anaerobic digester operation and startup here!

Anaerobic Digester Solutions

Anaerobic Food Supplement

- Provides COD and soluble micronutrients specific for anaerobic microbes, allowing better methane generation

- For use in anaerobic processes with variable loadings and of all types

- Provides more consistency in operations and methane generation

- Improves the digester microbiota, stabilizing the pH

BioGas1

- Provides consistent volatile solids conversion, a healthier population of methanogenic archaea, and a better quality of biogas production

- Contains ten soluble micronutrients that help convert acetate into valuable methane gas

- Ships non-hazard

About the Author

Dan McKeaton holds a B.S. in chemistry and started working at Aquafix in 2014. Dan performs wastewater research at Aquafix Inc and has presented his research in quaternary ammonium cations at the WEFTEC technical symposium in 2019. Dan also designs customer treatability studies in wastewater, assists in the development of wastewater products, and performs microscopic analysis for wastewater customers.